We at Sanforce are manufacturing professionals, which is why we have set up a strict quality policy and effective QC system to ensure everything is of top quality. From design to process and from parts manufacturing to finished goods testing, each and every step is fully analyzed. Our quality control department works in tandem in each and every phase and process. Together they ensure the top quality of the final product.

All the procured material go through thorough inspection before being used. This is done in order to ensure that all the materials we inspect are of top quality and thus build a high-end product tailored for your needs.

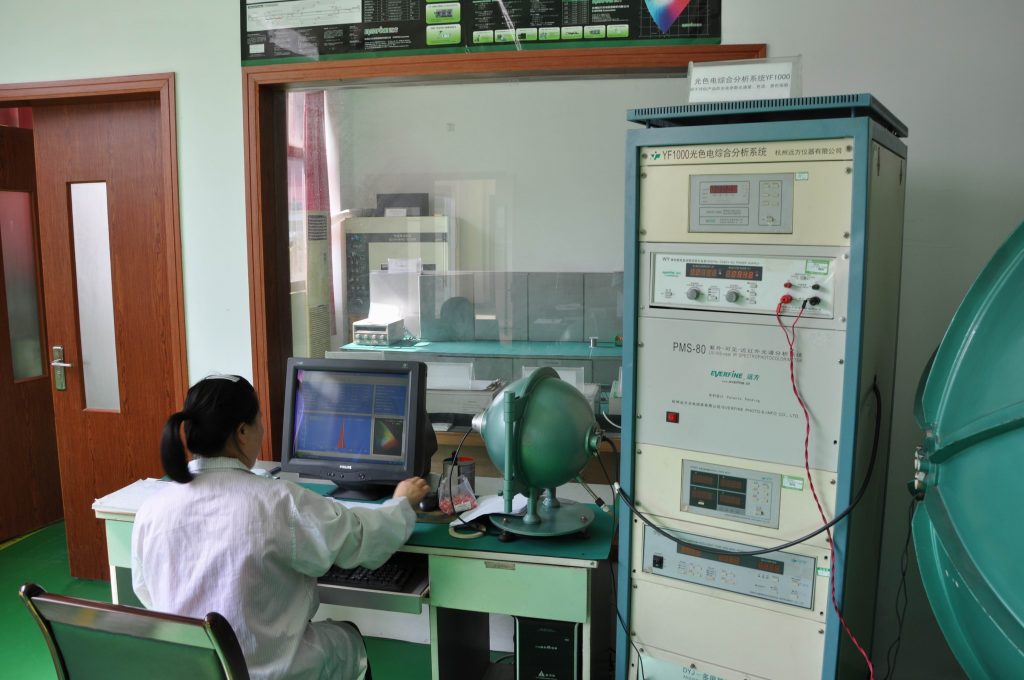

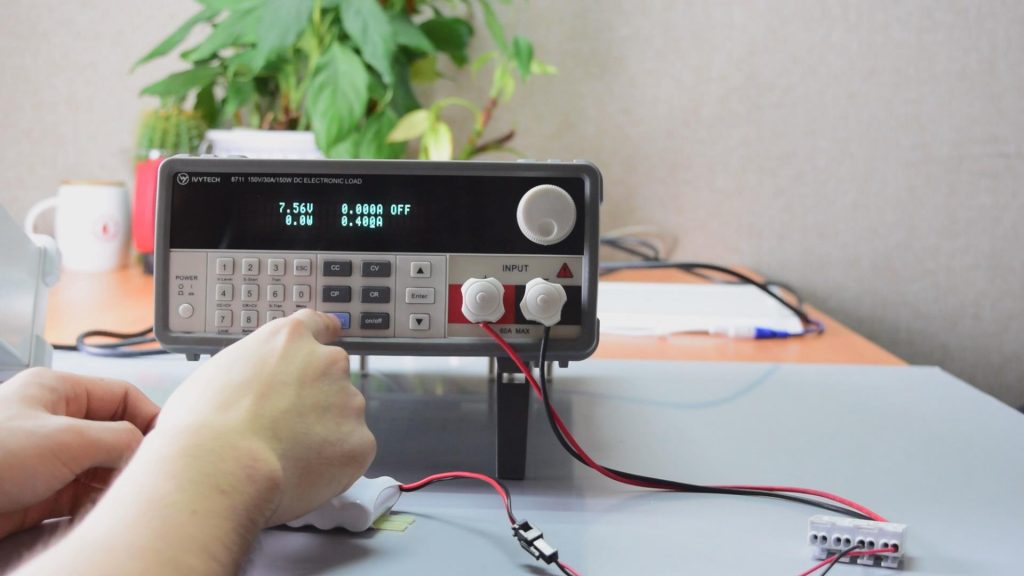

Once all of electronics is ready on PCB board, our engineers test whether the parameters meet the original design done by testing machine.

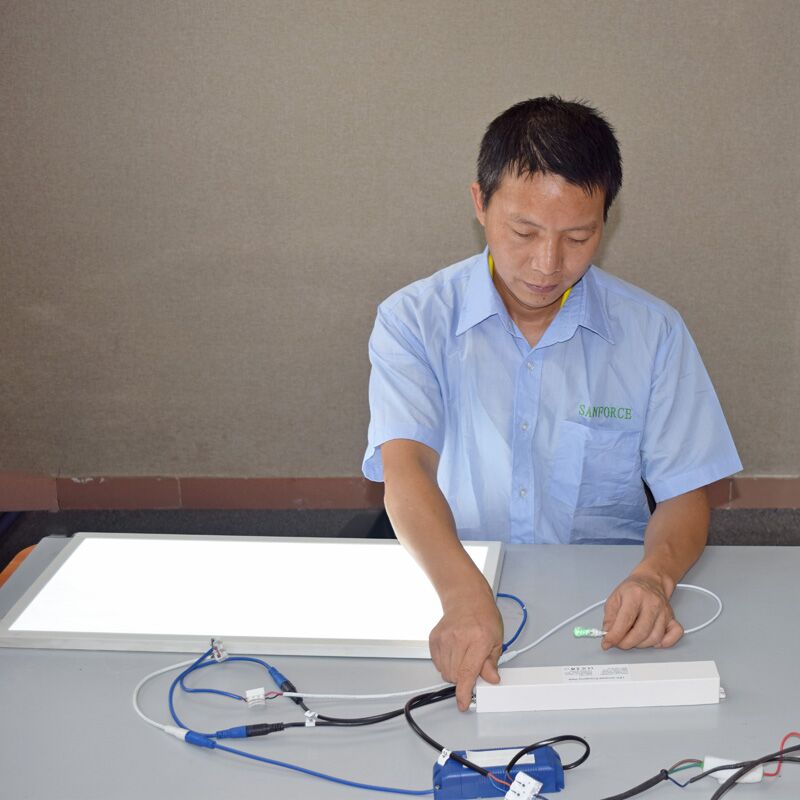

We perform the final test to ensure the full functionality of our products. Various aspects of the product are checked to make sure that they are as per the requirement of the customers.

Producing quality emergency ballast is a team effort requiring the joint support of the line operators, cleaning and changeover crews, and manufacturing/packaging management. Our inspection technologies provide accurate data readings, and they are backed up by the sharp senses of our inspectors, allowing us to faithfully meet your specifications.

Not sure what you required for your lightining project ?

Get in touch with us for FREE consultation.