South Africa regularly experiences power interruptions, from scheduled load-shedding to unstable grid supply and limited electricity in rural areas.

In this environment, reliable emergency lighting isn’t just convenient — it’s essential.

Whether in offices, schools, hospitals, or residential complexes, it keeps people safe, ensures compliance with local regulations, and maintains continuity when the lights go out.

Replacing entire fixtures can be expensive and disruptive, but emergency conversion kits provide a smart alternative.

These kits retrofit existing lighting systems to operate during outages, delivering backup illumination quickly and cost-effectively.

With the right kit, your building can stay fully functional, meet safety standards, and reduce long-term maintenance costs.

This guide will take you through how emergency conversion kits work, the technical specifications to prioritize, local compliance requirements, supplier selection, and real-world applications across South Africa.

By the end, you’ll be ready to choose a solution that maximizes safety, performance, and value — even when the grid fails.

Read more about LED Emergency Drivers & Safety in Brazil

What Is an Emergency Conversion Kit?

An emergency conversion kit, also called a retrofit module or emergency driver, is designed to keep existing luminaires operational when mains power fails.

It integrates directly into LED panels, downlights, or fluorescent fixtures, providing backup power without the need for a full luminaire replacement.

Core Components:

Upon power loss, the module instantly switches the light to battery power, maintaining safe illumination for a defined duration — typically 1 or 3 hours.

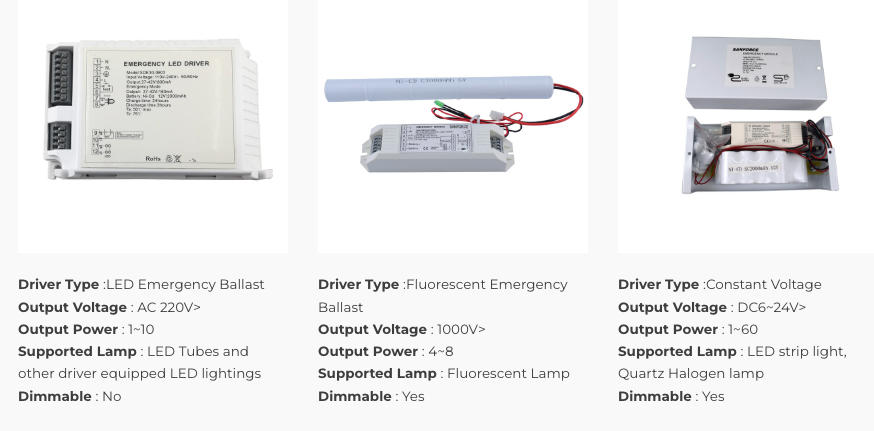

Types of Kits:

Choosing the right type depends on fixture compatibility, desired autonomy, and installation requirements.

Battery life is also critical; most kits, including Sanforce Tech models, recommend replacement every 4 years.

Read more about Emergency Lighting Drivers In Germany: Buyers’ Guide

Regulatory & Safety Requirements in South Africa

When installing emergency lighting, compliance with local standards is mandatory. Key regulations include:

Standards Highlights:

Implications for Buyers: Only certified kits with datasheets demonstrating end-of-life performance and self-test capabilities meet these standards.

Suppliers should provide type test reports and technical documentation for audits or compliance verification.

Key Technical Specifications to Prioritize

Match the emergency driver’s output to the luminaire’s power. Undersized kits may cause flickering, while oversized kits waste energy and may not fit.

Example: A 25W LED panel requires a driver rated at 25W or an adjustable range, such as Sanforce 6–25W modules.

South Africa uses 220–240V AC, 50Hz mains. The driver must match the LED’s forward voltage (e.g., 20–60V DC) and current (e.g., 300–800mA) to prevent damage.

Select a kit rated for at least 1 hour; critical facilities like hospitals may require 3 hours. Sanforce modules allow adjustable durations via battery pairing.

Battery chemistry affects longevity and reliability:

Automatic self-testing ensures compliance with SANS 10114-2, simplifies inspections, and provides visual indicators: green = normal, steady red = charging/fault, flashing red = battery failure.

Ensure compatibility with dimming controls (0–10V, DALI, PWM). Sanforce dimmable modules work with both dimmable and non-dimmable LEDs.

Check space availability for the driver and battery. Detached battery packs allow flexible installation; integrated drivers suit recessed or surface-mounted panels.

Aim for a minimum 3-year driver warranty and 1–2 years for the battery. Local support is vital for South African conditions.

Look for CE, RoHS, SABS, and ISO 9001 certifications, ensuring quality and compliance.

Learn more on Why LED Emergency Drivers Are Essential for Oman

Choosing a Reliable Supplier

The right supplier is as important as the product. Consider:

Commercial Offices: Retrofit panels or downlights for safe evacuation during load-shedding. Protect employees, maintain productivity, and ensure compliance with safety regulations.

Educational Institutions: Maintain visibility in corridors and staircases for student safety. Emergency kits simplify inspections and keep classrooms and libraries operational during outages.

Hospitals: Bridge the gap between power loss and generator start with 3-hour kits. Ensure uninterrupted lighting in operating rooms, wards, and emergency exits.

Retail & Hospitality: Keep customer areas safe and preserve lighting ambience. Emergency kits help maintain brand image, prevent accidents, and comply with safety codes.

Industrial Facilities: High-bay LED fixtures and task lighting maintain safety in factories. Protect workers, prevent production downtime, and meet occupational health standards.

Residential & Community Buildings: Stairwells, lobbies, and corridors remain illuminated. Reduce accidents in common areas, increase security, and provide peace of mind for residents.

Remote or Off-Grid Locations: Integrates with solar + battery systems for hybrid backup. Enable lighting in schools, clinics, and municipal facilities without reliable grid access.

Government & Public Buildings: Ensure emergency exits, corridors, and public service areas remain illuminated. Support safety for citizens during outages and compliance with municipal regulations.

Event Venues & Sports Facilities: Keep arenas, stadiums, and convention centers safe during unexpected blackouts. Protect attendees, facilitate emergency evacuation, and maintain operational continuity during events.

In all scenarios, emergency conversion kits are a cost-effective, safety-critical retrofit solution.

Know more about Emergency Conversion Kits Buying Guide for Jordan

Identify type, wattage, voltage, and dimming compatibility.

Conduct a detailed survey of all luminaires to determine their electrical characteristics and operating environment. Document fixture models and mounting locations to ensure that the chosen emergency modules and drivers will integrate seamlessly without voiding warranties or compromising performance.

1 hour (standard) or 3 hours (critical areas).

→ Determine the appropriate backup duration based on building codes, occupancy type, and risk category. Critical infrastructure such as stairwells, exit routes, and healthcare facilities often require extended duration, while general office or retail areas may suffice with standard backup.

Ensure proper output for your LED system.

→ Verify that the emergency driver output matches the fixture’s operating voltage and current to prevent under-illumination or premature component failure. Consider using manufacturer-recommended pairing charts or test results to confirm performance consistency.

LiFePO₄ for high-temperature or industrial environments.

→ Evaluate environmental conditions such as ambient temperature, ventilation, and expected lifecycle when selecting batteries. LiFePO₄ batteries offer excellent thermal stability, safety, and longevity, making them ideal for demanding or high-duty-cycle applications.

CE, RoHS, SANS compliance, and datasheets.

→ Always request official certification documentation and compliance test reports from suppliers. Ensuring that products meet recognized international and local standards helps mitigate liability, supports insurance compliance, and guarantees product safety.

Self-test and LED indicators simplify maintenance.

→ Automated self-diagnostic systems can significantly reduce manual inspection frequency by providing status indicators for charge level, lamp output, and battery health. This not only lowers maintenance costs but also ensures timely detection of potential faults.

Local support, proven reliability, OEM/ODM capability.

→ Choose suppliers with a verifiable track record, responsive after-sales support, and the ability to provide tailored solutions if needed. Proximity of support centers and the availability of spare parts can greatly improve system uptime and reduce logistical delays.

Include battery replacements and maintenance.

→ Move beyond initial purchase price by factoring in installation costs, periodic maintenance, and future battery replacements. A lifecycle cost approach provides a more accurate picture of long-term savings and supports better budgeting decisions.

Confirm performance before large-scale installation.

→ Run a small-scale implementation to observe real-world performance under varying conditions. Record charging times, discharge duration, and light output to verify compliance and identify any potential installation challenges before full rollout.

Keep commissioning, inspection, and battery logs.

→ Establish a clear documentation system to record test results, maintenance actions, and component replacements. Organized records not only simplify audits and compliance checks but also extend the overall lifespan of the emergency lighting system.

Stock essential batteries, drivers, and test kits to minimize downtime.

→ Maintain a strategic inventory of high-turnover components and test accessories to support quick replacements during routine maintenance or emergencies. This proactive approach ensures consistent illumination reliability and reduces disruption risks.

Reassess system efficiency, compliance updates, and emerging technologies for future upgrades.

→ Conduct yearly reviews to identify degradation trends, energy efficiency improvements, or new regulatory requirements. Incorporating newer, more efficient emergency lighting technologies can yield better reliability, safety, and sustainability outcomes over time.

Conclusion

In South Africa, where power reliability is unpredictable, emergency conversion kits are essential. They provide a practical, cost-effective way to retrofit existing lighting fixtures for backup operation without a complete overhaul.

Partnering with a trusted manufacturer like Sanforce Tech ensures:

Investing in a certified emergency conversion kit protects lives, ensures compliance, and provides peace of mind. Keep your lights — and your people — safe, even when the grid goes dark.

Visit Sanforce Tech to explore LED emergency conversion kits, drivers, and self-test modules, or request a consultation for your project.

Not sure what you required for your lightining project ?

Get in touch with us for FREE consultation.