Self-test emergency drivers are equipped with advanced sensors which help in the diagnostic process and to monitor emergency lighting systems. In Chinese manufacturing plants, operational safety is important due to the constant operation of machinery.

This proactive approach ensures that emergency systems are always in optimal condition ready to respond when needed. This proactive approach not only minimizes risks but also instills confidence in safety measures among plant personnel.

Self-test emergency drivers represent a paradigm shift in safety management, enhancing operational safety by ensuring continuous functionality of emergency systems, safeguarding personnel and productivity.

Operational safety is important in Chinese manufacturing plants due to the complex daily operations. Any kind of disaster can lead to severe consequences including injuries and financial losses. The potential risk for accidents in these plants is high, affecting not only production efficiency but also employee well-being.

Regular inspections, comprehensive training programs and promoting a safety culture among employees should be given priority in the Chinese Manufacturing Plants. This approach decreases the risks of accidents which creates a safer working environment that ultimately leads to improved productivity and profitability.

The complexity and scale of operations in Chinese manufacturing plants pose significant challenges to operational safety. The dynamic nature of production environments increases the risk of accidents. Traditional safety systems are outdated and lack real-time monitoring capabilities, leaving workers vulnerable.

Regular maintenance and inspection of safety equipment are also lacking. Inadequate training programs for employees also pose a challenge. Due to the complex landscape at local, national, and international levels it is very difficult to follow safety regulations.

To ensure operational safety a different approach is needed like modernizing safety systems, implementing regular maintenance protocols, enhancing employee training programs and ensuring compliance with regulations.

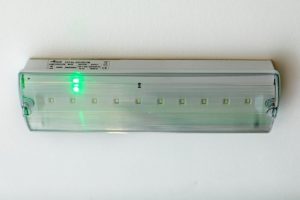

Self-test emergency drivers represent a significant advancement in emergency lighting systems, offering an automated solution for ensuring functionality and readiness during critical situations. Let’s delve into a detailed understanding of these innovative devices.

Self-test emergency drivers are cutting-edge devices engineered to automate the diagnostic process of emergency lighting systems. The traditional systems used to require manual testing at periodic intervals, self-test drivers conduct self-checks automatically. These drivers are integrated into emergency lighting systems to monitor their performance continuously, ensuring they remain operational and ready to activate when needed most.

Self-test emergency drivers use advanced algorithms and sensors to assess emergency lights, batteries, and circuits at predefined intervals. They measure parameters like light output, battery voltage, and circuit integrity, comparing them against performance standards. The system triggers alerts for immediate action. This approach enhances the reliability and readiness of emergency lighting systems. It ensures operational safety in various settings like manufacturing plants, commercial buildings, and healthcare facilities.

Self-test emergency drivers have lots of benefits that enhance the reliability, efficiency, and effectiveness of emergency lighting systems. Let’s view these advantages in detail:

Integrating self-test emergency drivers into Chinese manufacturing plants requires careful planning, execution, and adherence to regulatory standards. Let’s delve into a detailed understanding of how these innovative devices can be seamlessly integrated into existing safety infrastructure:

Shenzhen Tech Electronics Co. Ltd. located in Shenzhen, China faced frequent disruptions in their work. The main reason was power outages and emergencies. In 2019, the plant installed self-test emergency drivers as part of its safety protocol. During a sudden power outage in 2020, the self-test emergency drivers activated emergency lighting systems by illuminating critical areas and escape routes.

As a result, production downtime was significantly reduced allowing operations to resume swiftly once power was restored. The nature of the self-test drivers ensured that the plant could maintain essential operations even during emergencies by minimizing disruptions and reducing financial losses.

The Shanghai Auto Works Automotive Manufacturing Plant

The Shanghai AutoWorks Co., Ltd. Manufacturing Plant, situated in Shanghai, China, in order to recognize the safety of its workforce it took the initiative to enhance its emergency response capabilities.

In 2018, the plant installed self-test emergency drivers as part of its safety protocol upgrade. During a fire incident in 2019, the self-test emergency drivers automatically activated emergency lighting systems and it provided illumination for safety personnel which helped them to navigate and evacuate the premises swiftly. The improved response time enabled the safety personnel to put off the fire and -the safety of employees. This response was possible due to the automated diagnostics and readiness provided by the self-test emergency drivers.

Some individuals believe that self-test emergency drivers are unnecessary because existing safety measures are sufficient.

It’s very important to provide information to stakeholders regarding the benefits of self-testing emergency drivers in order to enhance the operational safety. The traditional safety measures are also important.

The self-test emergency drivers offer protection by continuously monitoring and assessing emergency lighting systems. The manual testing which may lead to human error. The self-test drivers automatically diagnose the process by ensuring the emergency lights are always functional and ready for activation during critical situations.

By identifying and addressing potential issues of the self-testing of emergency drivers which enhance the reliability and effectiveness of emergency lighting systems, ultimately contributing to a safer working environment for all personnel. While existing safety measures play a vital role, self-test emergency drivers offer unique advantages that complement traditional approaches, making them a valuable asset in ensuring operational safety.

In conclusion, the implementation of self-test emergency drivers represents importance in enhancing operational safety within Chinese manufacturing plants. These innovative devices offer proactive solutions to decrease the risks during emergencies. Self-test emergency drivers play a crucial role in safeguarding both personnel and productivity. As Chinese manufacturing plants continue to prioritize operational safety, the adoption of self-test emergency drivers stands as a testament to their commitment to excellence and innovation in safety management.

Self-test emergency drivers continuously monitor and assess emergency lighting systems, ensuring they are always functional and ready for activation during critical situations. This proactive approach enhances overall safety by reducing the risk of failure.

Unlike manual testing, which may be prone to human error, self-test emergency drivers automatically diagnose the emergency lighting process. This automated process enhances reliability and effectiveness, complementing traditional safety measures.

Self-test emergency drivers identify and address potential issues, ensuring that emergency lighting systems remain reliable. This contributes to a safer working environment for all personnel, enhancing operational safety.

Self-test emergency drivers offer unique advantages that complement traditional safety approaches. By proactively monitoring and maintaining emergency lighting systems, they enhance overall safety and reliability, making them invaluable assets in ensuring operational safety.

By continuously monitoring emergency lighting systems and automatically diagnosing any issues, self-test emergency drivers ensure that critical safety equipment is always operational. This proactive approach helps prevent accidents and promotes a safer working environment for personnel.

Not sure what you required for your lightining project ?

Get in touch with us for FREE consultation.